Springs are a mechanical invention used in almost everything, from furniture to cars. They function due to their physical properties, which allow them to form proportional relationships with the force applied to them. This allows them to compress or extend at great speeds and makes them very useful in parts that require a burst of movement. There are many different types of springs, and a reliable spring manufacturer in Ohio will be able to provide them for you, based on your needs. Here are some of the most commonly used types of springs that you are likely to need.

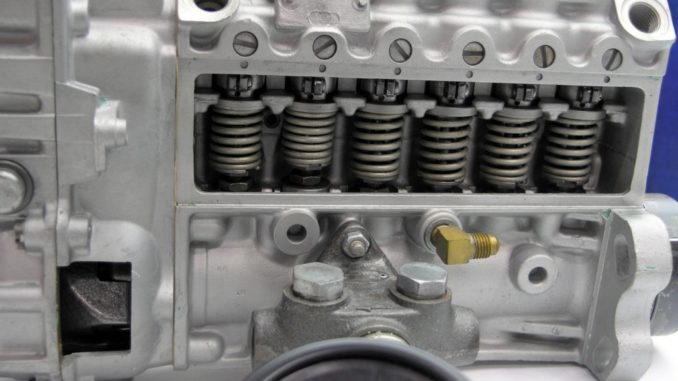

Compression springs

These types of springs are helical in shape, as most springs are. A compression spring is tightly coiled, though it’s natural position is extended. The tight coils allow it to release the most amount of force when it is compressed. It is useful only when it is compressed. When it returns to its natural shape, it pushes forward with a great amount of energy. This is the mechanism used in almost anything that you use in your day-to-day life. If you click on a pen to make the nib appear, you are using a compression spring. If you load a toy gun, you are also using the same mechanism.

Extension springs

These are the opposite of compression springs. They can be extended, and the energy they generate is when they return back to their compressed position. They generally have hooks attached to them, which allows them to pull back objects to their original positions. You are most likely to encounter this type of spring in automatic doors or certain types of tools such as pliers. It is more common to face problems such as loss of elasticity with extension springs. They need to be carefully calibrated so that too much force is not applied to them. They won’t return to their tightly compressed initial positions.

Torsion springs

These work in the same way that extension springs do. They are tightly compressed, and they have opposing forces twisting two ends of the spring. When released, this causes torsion springs to release a burst of energy. But instead of being applied in a linear fashion, the energy is in the form of torque or basically rotational force. Torsion springs are very useful in making clocks. They are also widely used in a car’s suspension system.

Constant-force springs

These springs are one of the few types of springs that are not helical. Instead, they are tightly coiled around an object such as a drum. When the free end is unspooled and attached to a force, the other end maintains a constant force. This is the reason they are called constant-force springs. You can commonly find these in contraptions such as seat belts.

There are many more types of springs used for highly specific purposes. The research one can do on them is never-ending, so it is best to find out what kind of spring is required for your job first.